Design for Manufacturing

Analysis of 3D-parts regarding manufacturing design guidelines

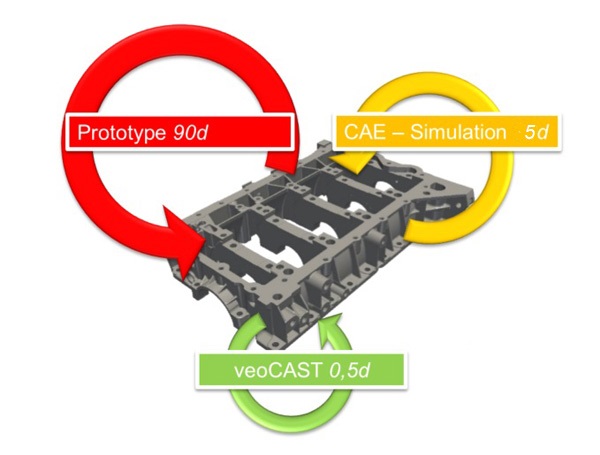

Product developers face a continuous growing challenge to meet functional requirements as well as the demands of the manufacturing processes when designing new products. A cast prototype or CAE simulation offer support and further insights.

But often product designers need their feedback faster!

Using Teraport’s Design for Manufacturing workbench veoCAST, designers can quickly and easily analyze their parts and minimize the risk of multiple optimization cycles due to overlooked manufacturing process demands. Fueled by the demands of our customers we developed a tool to check if the requirements of die cast manufacturing are met. By quickly and easily analyzing the often complex requirements within the design departments, problems get recognized earlier and thus optimizations are way more cost efficient.

Besides the use in design departments, more and more customers also use veoCAST in technical purchasing processes. Foundries enhance their RFQ process by the application of veoCAST in technical sales support.

Features:

- • wall thickness analysis using iso surfaces and colormaps

- • analysis of local maxima and minima

- • calculation of geometrical differences

- • projection of part geometry to a plain surface to evaluate hold down pressures

- • surface analysis (asign surfaces to the upper or lower part of the tool, analysis of draft angle)

- • calculation of undercuts

- • schematic tool draft generation

- • inner and outer edge analysis

- • identification of small gaps

- • interfaces to various CA-environments (CATIA/ ProE/Creo / SolidWorks / NX / JT / Parasolid / STEP)

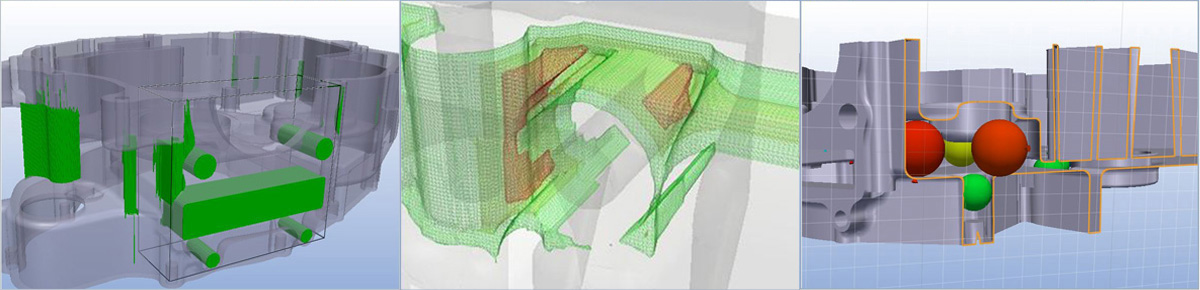

undercuts, isosurface-analysis and material accumulations

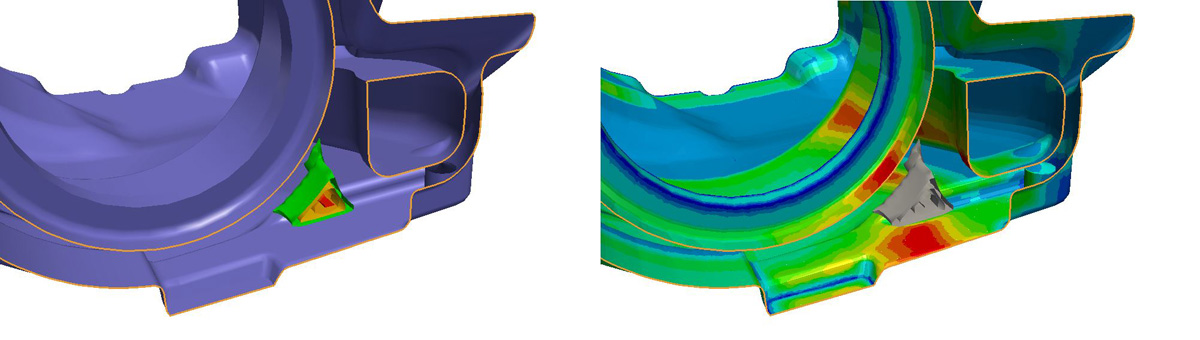

isosurface-analysis and derived thickness-color map on part surface

New Features Version 7.8 (3/2024):

-Feature Edges: The surface edges from CAD are visualized for improved analysis.

-Surface-based Undercuts (beta): Precisely calculate undercuts for more accurate evaluation.

-Performance Improvement: Optimized calculations for especially large components.

New Features Version 7.7 (5/2023):

-Automatic parting line: let veoCAST automatically find a mold opening direction without undercuts or let it optimize the undercut volume!

-Performance: Loading and saving of scenes has been optimized

-Part properties: Calculation of package size, volume and weight

New Features Version 7.4 (4/2021):

–Customize the report: Define the content and appearance of veoCAST reports, integrate your company logo, define the order and details of the result display.

–Exchange file: Easily share the complete analysis results (including all 3D data) with colleagues using a single file.

New Features Version 7.2 (7/2020):

–Template-Management: Export your settings as company defaults for component families and casting processes, define company standards for your veoCAST analyses.

–Extended quick check: Start the analyses maxima, minima, gap dimensions, isosurfaces, surface depth, inner edges and outer edges with the push of a button.

–Isosurface animation: Save GIF animations of the isosurfaces.

New features version 7.1 (3/2020):

–Format support for STEP data: Load neutral STEP data from any CAD system directly into veoCAST.

–Menu option “Filter Results”: Filter existing results without the need for recalculation. The processing of the results can be subdivided spatially by the filters, e.g. by hiding certain spatial areas for the time being. Furthermore you can filter by wall thickness or ratings (see screenshot).

Improve product quality, shorten development cycles, save redesigning costs by following a first-time-right approach. Experience how you can improve your design process using Teraport’s Design for Manufacturing Workbench. Get a free evaluation license!