Pro.FluidAnalyzer

Client Requirements

The simulation of fluid levels and behavior in the virtual vehicle serves to provide information at an early stage, which is of significant importance for the vehicle’s subsequent practical operation. This is not about lengthy and complex CFD analyses (computational fluid dynamics), but about significant insights which are gained in the course of the design process. We are talking about the filling and draining of reservoirs/tanks, or closed cycles, in respect of their employment in practical operation. For example, in the development of fuel tanks, information on the total volume, on the contained residual volume after draining, or on its functional capability in extreme situations – i.e., whether fluid can be extracted in the case of uphill driving – is of great importance. If these insights can only be gained from the physical prototype, the possible modification costs of a component can be significantly higher than in the initial (digital) development phase.

Teraport Solution

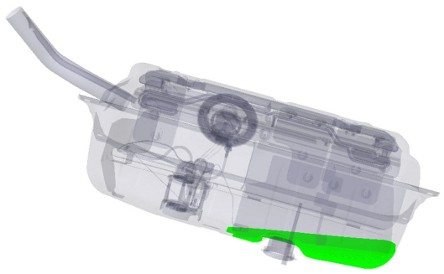

With Pro.FluidAnalyzer, volume and filling capacity analyses for the most diverse areas of operation can already be carried out on the digital prototype. In addition to the reservoir/tank which is to be examined (CAD geometry), the parameters must be selected in accordance with the set task; i.e., is it the total, the maximum or the minimum volume, etc which is to be determined. These requirements can be defined with the user interface DMU.Connect. If extreme situations, i.e., uphill driving, are to be simulated, the corresponding general requirements must also be specified. In addition to the purely numerical values, the user also receives the result of the analysis in the form of geometry models of the determined volume.

Benefit for the Client

The Teraport solution provides the simulation results within a very short period of time (in some cases within minutes). These results inform the design engineer of possible problems which could occur in practical operation. On the basis of these results the design engineer can check whether the demands which will be made on his design correspond with the performance specifications and/or if problem areas have surfaced which have not yet been taken into account. A major benefit for the client is a higher degree of reliability and an increase in the quality of the digital product. Problems are identified at an early stage and hence do not only appear in the physical prototype. This permits an ongoing contribution to the reduction of costs.