Pro.DataReducer

Client Requirements

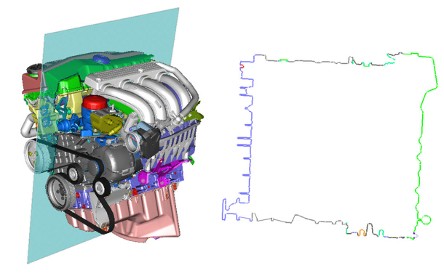

The ever increasing complexity of products results in a continual increase in the amount of geometric 3D data. Despite a significant increase in hardware performance, the limitations of the visualization and engineering systems are constantly being reached. It therefore continues to be essential to reduce 3D mass data and to preprocess this data for data exchange or for subsequent processing. Furthermore, the geometrical details are often not required or desired for the subsequent processing or data circulation. For example, manufacturers of engine test benches do not require detailed information; but they do require the engine dimensions as early on as possible in order to ensure that the testing and inspection facilities to be produced can be manufactured parallel to engine development and with the appropriate lead times.

Teraport Solution

With the Pro.DataReducer process solution, 3D mass data or individual models can be reduced quickly and automated using a variety of approaches: Either the inner geometries are excluded by gutting, or the polygons of the model surfaces are processed. The accuracy or the acceptable amount of fuzziness of each data reduction option can be altered easily and without difficulty with the Teraport user interface DMU.Connect. Both the reduced model and all the detailed information on the calculation are subsequently stored.

Benefit for the Client

An engine comprising approximately 7 million triangles can, for example, be reduced to 1.5 million triangles without a loss of quality becoming apparent on the model surface. Additional potential of up to a total of 90% can be achieved in the case of models acting purely as placeholders. It is of particular advantage that the calculation can run in the background and that other applications such as, for example, CAD Systems, are hence in no way affected.