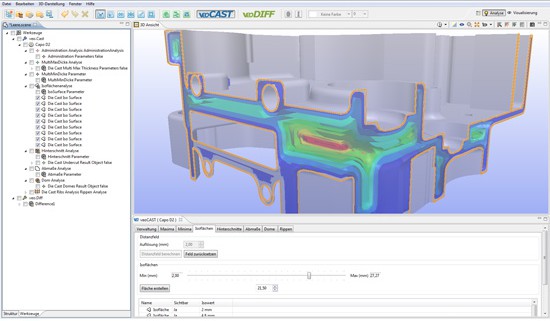

veoCAST: check 3D part-geometry for effective manufacturing

In early October, Teraport GmbH in Munich introduced its latest product with veoCAST. The workbench allows 3D parts to be checked to see whether they meet the requirements of casting processes in the final stages of development. Driven by the idea of customers who were not able to find what they wanted on the market, Teraport developed a workbench that above all offers a comprehensive range of functions. Simple interfaces and easy and fast operation. “We want to speed up hedging cycles. A CAE casting analysis provides comprehensive insight into the process, but it also takes time and requires specialists. We have taken on the task of creating a tool for designers that does not require a lot of training and delivers results directly in the shortest time. A “rapid check”, so to speak. According to the feedback from our pilot customers, we were very successful,” says project leader Dr. Stefan Wittmann. The first opportunity to introduce the achievements of the new software to a critical professional audience presented itself at the symposium Design for X 2005 on 7 and 8 October in Herrsching. At the event held by the Institute for Technical Product Development of the Bundeswehr University Munich and the Chair of Engineering Design at the Friedrich Alexander University of Erlangen, Nuremberg Dr. Wittmann and Dr. Alexander Koch from the Knorr Bremse Systeme für Nutzfahrzeuge GmbH jointly presented how the theoretical principles of the discipline “Design for Manufacturing” are used in a practical software tool as a joint project. This ability to customise the product development process more efficiently is now available on the broad market with veoCAST.

Find out about veoCAST here and ask for a free trial!