Strong interest in mido at Moldplas 2025

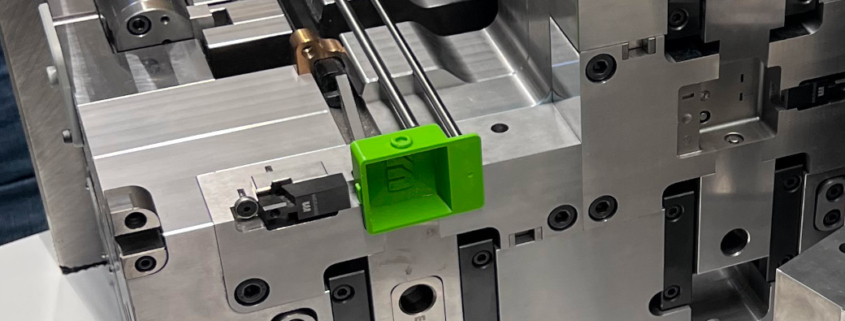

The Moldplas 2025 trade fair, one of Portugal’s most significant industrial events, took place from 13 to 15 November at Exposalão in Batalha (Leiria) and attracted more than 15,000 professional visitors. With over 250 exhibiting companies and dedicated areas such as 3D Additive Expo, i4.0 Expo and Subcontracting, the event provided a broad view of current technological developments and digital production trends.

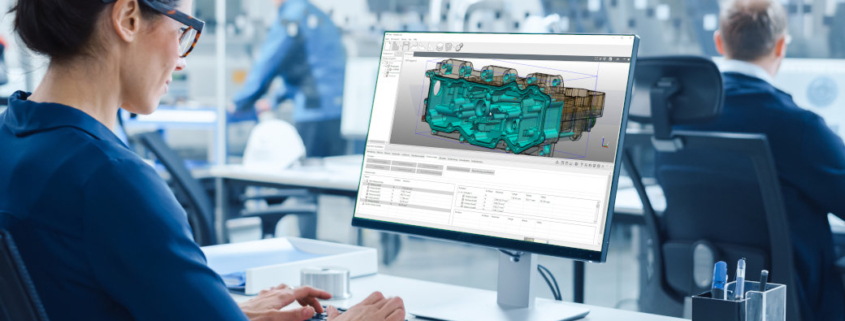

Rather than focusing on a traditional product demonstration, Teraport engaged directly with visitors and presented mido through concrete application scenarios. It quickly became clear how precisely the software analyses CAD models and translates them into transparent, consistent tool cost calculations. This practical approach resonated strongly, especially within the Portuguese tool and moldmaking sector, known for its agility and strong industrial drive.

“Many discussions at Moldplas showed how important fast and transparent tool cost evaluation is for Portuguese industrial companies,” explains Philipp Hübner, Product Manager for mido. “With mido, we demonstrated live how easily complex CAD geometries can be analysed and turned into reliable cost structures.”

Visitors particularly appreciated the short calculation times and structured reports that make mido a trusted tool in early development phases. The fair also offered valuable opportunities to connect with moldmakers and manufacturing companies from the Leiria region – one of Portugal’s most dynamic industrial hubs.

“Moldplas clearly highlighted the momentum within the Portuguese tool and moldmaking industry,” emphasizes Raphael Heilig, Managing Director of Teraport GmbH. “mido enables companies to achieve greater process stability and maintain transparent cost control – essential qualities in a rapidly evolving, digitally oriented market.”

With its strong presence at Moldplas 2025, Teraport strengthens its footprint in Portugal and reinforces its role as a reliable partner for companies aiming to modernise and safeguard their costing processes.