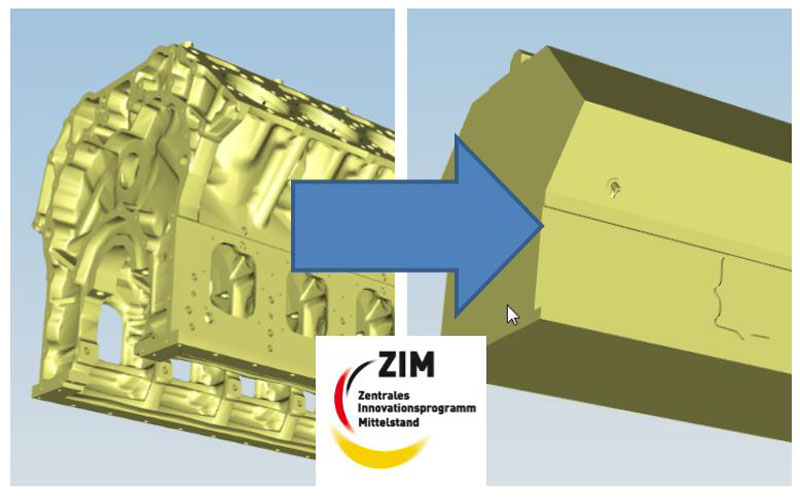

The Central Innovation Programme for SMEs (ZIM) is a nationwide funding program, open to all technologies and sectors, of the Federal Ministry for Economic Affairs and Energy. Teraport GmbH has been engaged in developing the framework since 2014 with the implementation of an innovative development project.

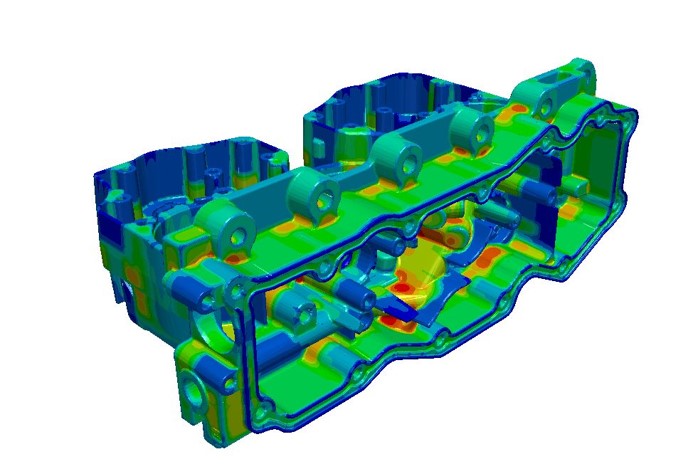

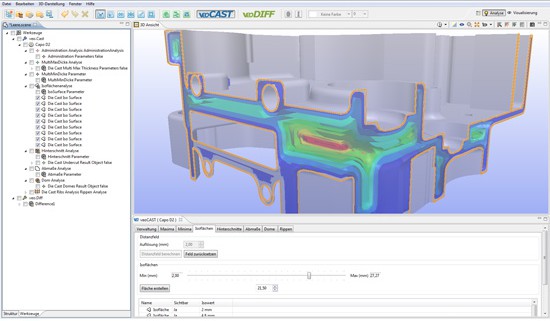

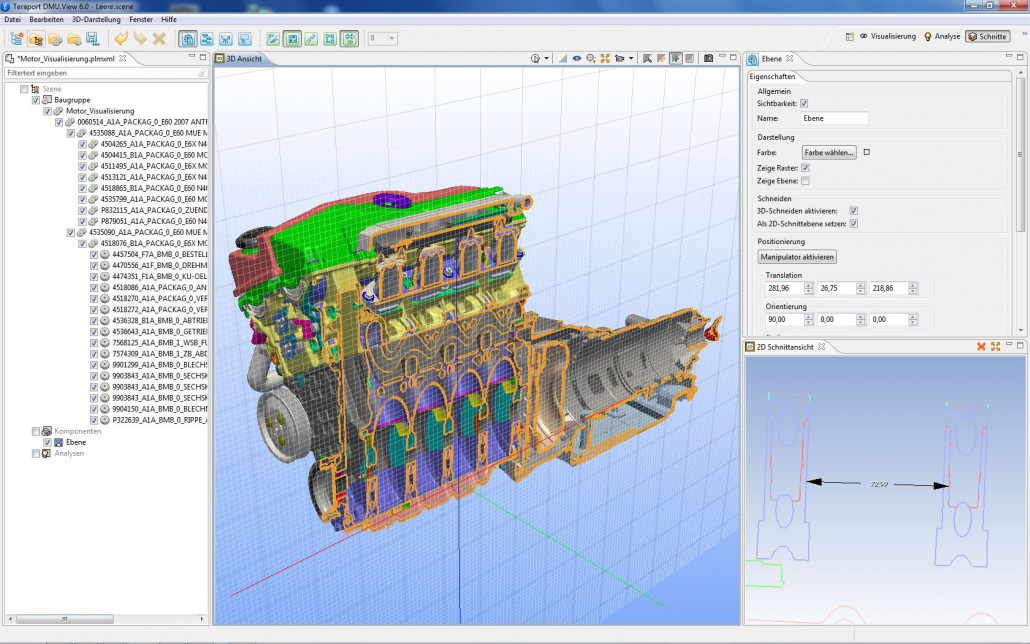

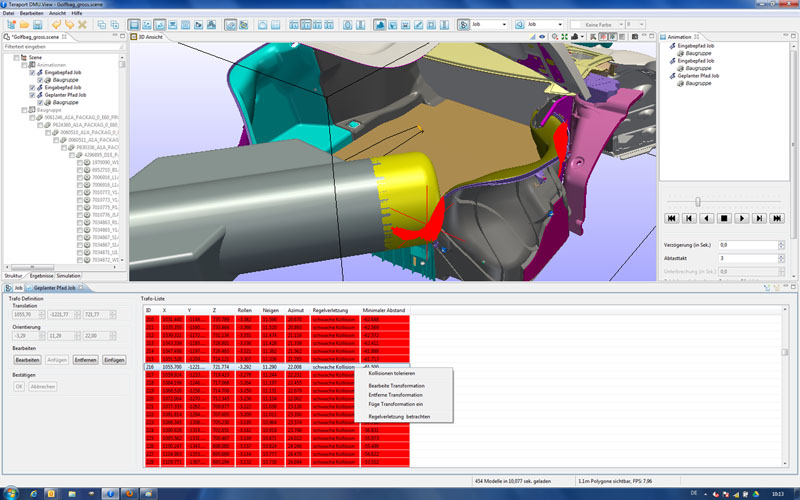

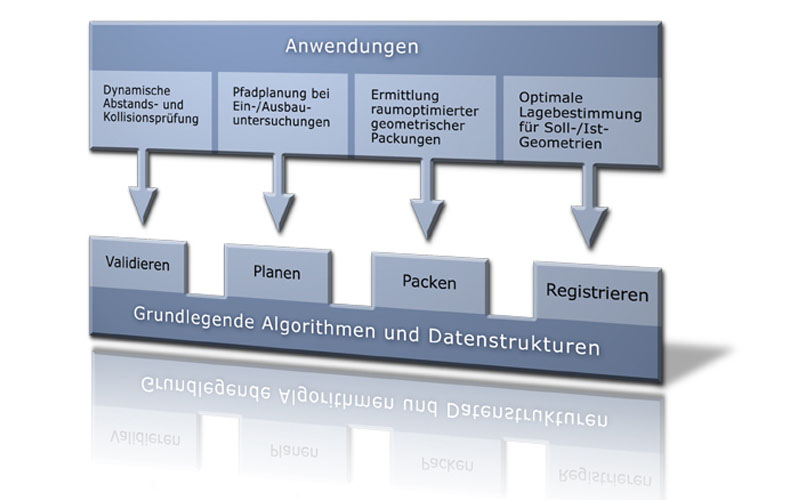

At that time, computer-aided design (CAD) systems were used to create detailed models of complex assemblies. However, this is often only the outer shell of the important assemblies, for example, for visualization or construction followed by supply of parts for many other process steps. For the sake of performance, for example, in the design of complete systems (cars, trucks, airplanes, ships, etc.) and it is the process of removing internal structures in terms of confidentiality in the transfer of CAD data to customers and suppliers. To automate the so-called pitting process, Teraport has released tenders for the DMU SurfaceFIlter module on the basis of so-called triangles approximated by CAD data. Tessellated surfaces are surfaces where all invisible triangles are removed and only the visible triangles are inserted into the pitted model edition.

Under the current ZIM project, Teraport wants to expand its offering to include an additional module. At the heart of the development of software stands a program called “DMU.SurfaceFilterXT”. This is a reliable and simplified CAD Model created based on exact area dimensions. In addition to the automation process which has to be carried out manually, at present, it is also important, in certain places, to simplify the outer shell (e.g. clogging) and retain the same number of interfaces (connections/flanges). Even Marcus Trommen, head of software development, is extremely pleased with the current development of the project:

“We are confident that we can bring a powerful product in the market to expand our presently diverse portfolio in the future.”

This project is included in the Central Innovation Programme for SMEs (ZIM), following a decision of the German Bundestag supported by the Federal Ministry of Economics and Energy.