Mido impresses at the WBA annual conference in Aachen

At the end of November, the year seems almost over, but as usual, a very special highlight awaits the tool and mold making industry. The Toolmaking Academy Aachen, under the direction of Prof. Dr. Boos, is calling for the annual meeting. In addition to stimulating discussions about the future of tool and mold making, especially in the field of international competition, the “Excelence in Production” award “Toolmaking of the Year” was also on the agenda. The award ceremony took place in the historic Coronation Hall of Aachen City Hall, where emperors and kings received their insignia eons ago.

The winners can be admired on the EiP website.

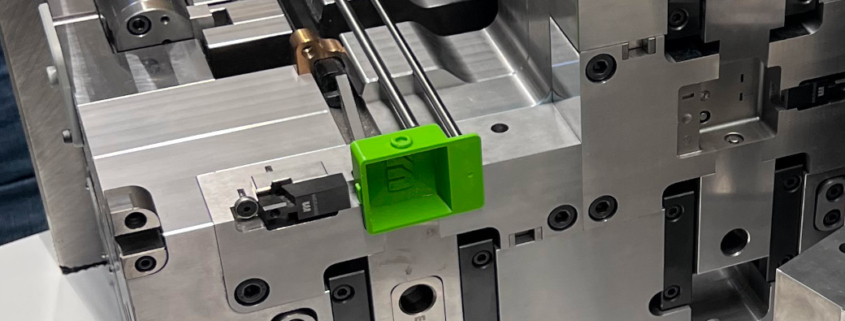

The event was framed by a trade exhibition. Here, experts presented future-oriented products and solutions for all aspects of tool and mold making. And ‘mido’ the “Next Generation Tool Cost Calculation” was of course also there.

“We can draw a thoroughly positive conclusion,” said Teraport Managing Director Raphael Heilig after the event. “The WBA Annual Meeting offers a perfect platform for networking. Not only did we receive very good feedback on our mido solution, but we also gained many new impressions of the functions that such software will need in the future. Keywords such as “CO2 footprint”, big data and better standard manufacturer connection are just a few of the points that will soon be on the mido feature list.”

For more information about mido and how it can help you, visit https://vxmido.com.