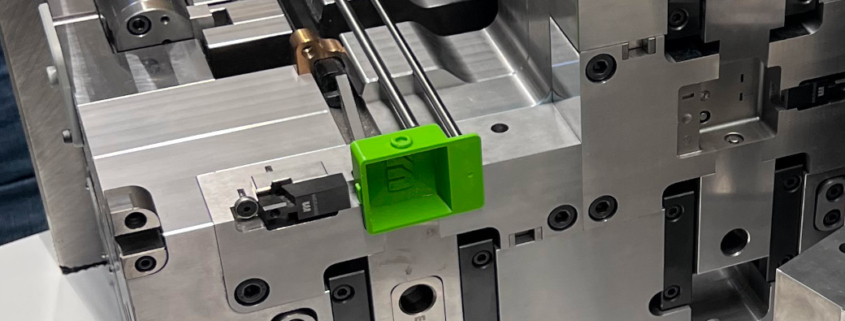

Teraport is the latest organization to join the Altair Partner Alliance, where it will offer its veoCAST software. veoCAST is a stand-alone software designed to analyze CAD parts for conformity with casting process requirements.

veoCAST enables users to quickly and easily analyze all relevant part criteria without the need for FEM casting simulation, helping detect and eliminate potential problem areas early in development. veoCAST is particularly beneficial in the CAD part development, technical purchasing, and foundries’ request for quotation (RFQ) processes. By incorporating veoCAST into their workflow, Altair customers can create optimal designs, streamline the procurement and sales processes, and bring their products to market faster and with higher quality.

veoCAST offers significant advantages to foundries, particularly in enabling quick responses to request for quotations (RFQs). It facilitates the identification of potential manufacturing problems in supplied CAD parts and the proposal of necessary modifications at an early stage. This results in more accurate quotes and technical solutions, fostering successful collaborations and enhancing customer satisfaction.

Some of veoCAST’s top capabilities and benefits include:

Optimize Designs Early: With veoCAST, design engineers can quickly analyze a part’s conformity with casting process requirements, detecting potential problem areas early on and ensuring the design is optimized for manufacturing.

Streamline Supplier Selection: Technical purchasing departments can use veoCAST to build a strong understanding of the manufacturing requirements for casted parts, enabling them to make informed decisions when choosing casting part suppliers.

Accelerate the Quotation Process: Foundries can use veoCAST to quickly identify potential manufacturing problems in the supplied CAD parts and propose necessary modifications, leading to more accurate quotes and technical solutions.

Specialized Casting Analysis: Conduct specialized casting analysis like customized wall thickness analysis tailored to engineering needs, gap detection, undercut calculation, draft angle analysis, and edge curvature analysis, which aren’t available or as specialized in CAD and simulation tools.

Faster Decision-Making: Make qualified decisions based on firsthand information using features like “one-click analysis” with templates, and comprehensive reports, which accelerate the decision-making process.

“Our veoCAST technology is going to be an immense addition to Altair customers’ toolkit that will complement Altair’s existing suite of products by providing specialized capabilities and making Altair’s overall offering more comprehensive,” said Raphael Heilig, managing director, Teraport. “We look forward to being a part of the APA, which gives us access to Altair’s extensive global customer base and affords us opportunities to collaborate with other members of the APA, potentially leading to joint ventures, co-development of new technologies, and/or other mutually beneficial partnerships.”

To learn more about Teraport and its veoCAST technology, visit https://web.altair.com/2023-webinar-veocast