Mido Impresses at Fakuma 2024

From October 15 to 19, 2024, Friedrichshafen once again became the hub of the international plastics processing industry. Teraport was proud to participate, shining a spotlight on “mido”, its revolutionary tool cost calculation software that sets new standards for efficiency, precision, and simplicity.

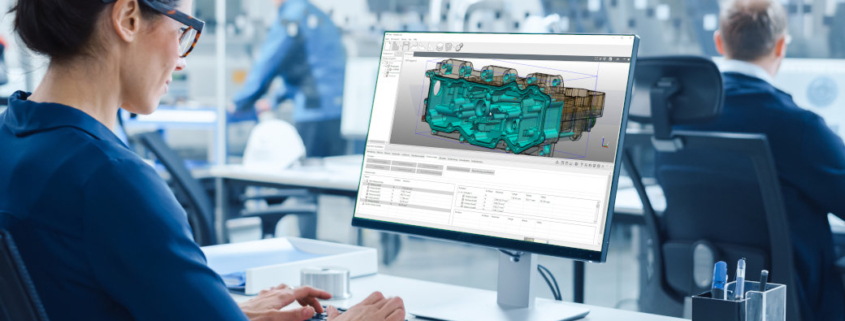

“mido” enables users to derive precise tool cost calculations directly from 3D CAD models—quickly, accurately, and effortlessly, even for non-experts. Its seamless CAD integration, automated cost driver analysis, and intuitive interface make it an essential tool for early-stage project decisions. The software delivers a comprehensive cost breakdown, covering production, material, and purchased part costs in just a few clicks.

Raphael Heilig, CEO of Teraport, explains:

“With “mido”, we aim to make tool cost calculation as straightforward and transparent as possible. Early cost clarity is critical in ensuring project success, and Fakuma provides us the perfect platform to demonstrate how “mido” makes a tangible impact.”

During Fakuma, visitors were able to experience “mido” firsthand through live demonstrations at the Teraport booth. The team demonstrated on site how the software can be efficiently integrated into existing workflows, helping businesses save time, reduce costs, and enhance overall project outcomes.

“The positive feedback we’ve received motivates us to continue enhancing “mido” and solidify its position as a market leader in tool cost calculation solutions,” adds Philipp Hübner, Product Manager for “mido”.

Get inspired by “mido”! Visit www.vxmido.com to learn more and request your personal test license.