Research project RASAND: Teraport GmbH as a cooperation partner of the University of Applied Sciences (HfT) Stuttgart and University of Mainz

The complex and challenging requirements in developing Digital Mockup software solutions call for a permanent examination of new technology and innovations. Therefore Teraport GmbH is eager to invest into research and development so that they can offer their customers algorithms state of the art.

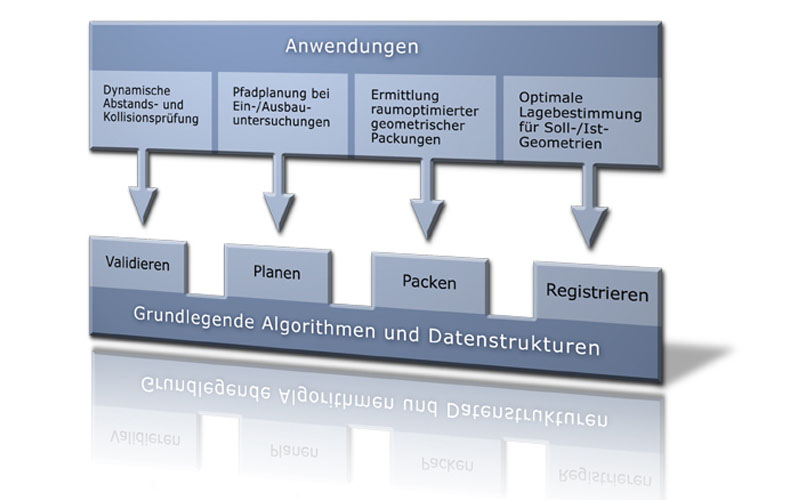

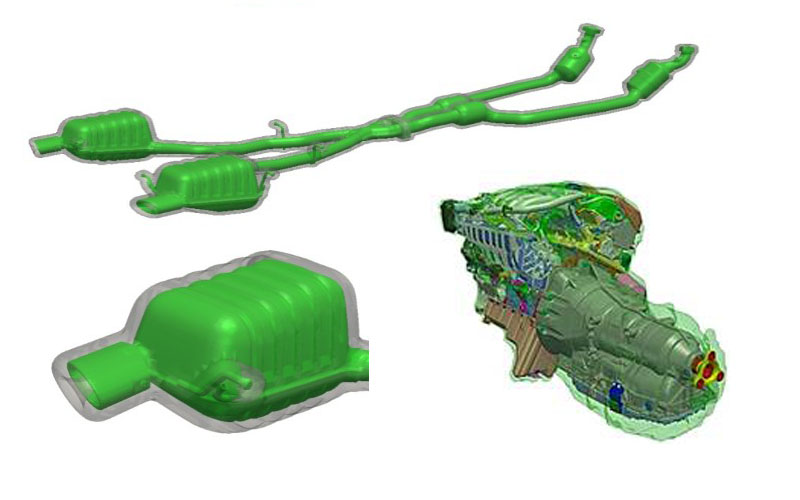

Teraport GmbH is pleased is pleased to announce a partnership with HfT Stuttgart and the University of Mainz two competent partners in the scope of science specialized on complex algorithms. In the context of a funded project of the “Federal Ministry of Education and Research” (BMBF) named “FHProfUnt” (Research on Universities of applied sciences in cooperation with companies) Teraport GmbH as an industrial partner realizes a research program with the two universities. The BMBF assessed the joint project named RASAND (Robust algorithms for distance calculations with great amounts of moving triangles) despite rigorous selection criteria as high innovative and as a result ensured the funding. The goal in RASAND is to develop new approaches for dynamic distance analysis of movable components in complex products as for example automobiles. Mrs. Prof. Wolpert the proposer from the HFT Stuttgart defines the goals as follows: “In RASAND we want to develop algorithms and software which execute efficient and reliable distance analysis for movements consisting of triangle mass data. In order to manage the large amount of data the new algorithms will especially make use of the parallelization mechanisms of modern hardware.”

Read more