Special technology gives a competitive edge!

Teraport GmbH offers its customers an unique combination of engineering-expertise and software-solutions regarding digital prototypes. That way Teraport’s engineers whenever they work in projects distinguish by their ability to optimize processes and methods by applying Teraport’s own software toolbox (DMU-Toolkit). The FES GmbH, Teraport’s latest customer is now making use of this proven concept. The engieering service provider offers added value along the complete product-lifecycle, especially topics like concept and package-development, conception of body-in-white and electrical-systems, chassis development, quality control and technical documentation are in their focus.

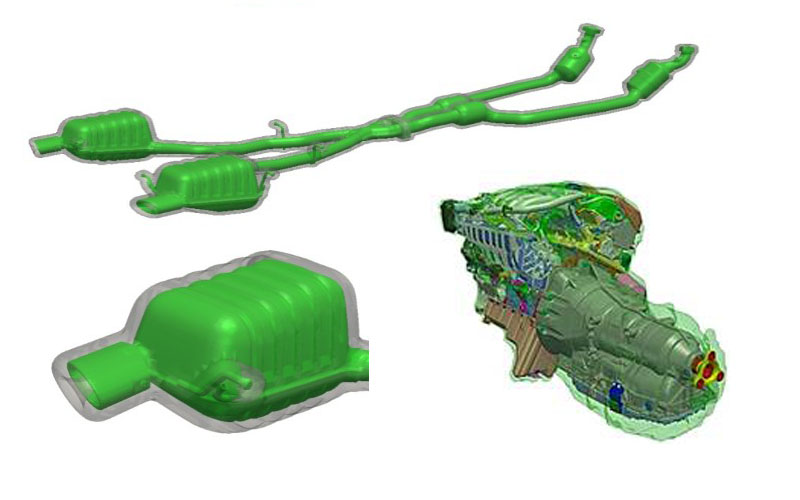

Most important for the decision to use Teraport’s Pro.PathFreezer at FES was its use at major car manufacturing companies. the software itself calculates envelope-models over dynamic movements. That way processes like vibrations of an engine, seat-kinematics or demounting procedures can be represented by a static 3D-model. That geometric representation of the movement in turn can be reimported to a PDM system to keep the developers focus on not violating the movements needed space. The Workflow, which is triggered via DMU.Connect, a flexible user-interface that can interact with 3D-data of every common CAD-program, stands out through high performance and accuracy compared to standard DMU-Tools. This ensures that large 3D-models can be calculated moving over thousands of trajectories as well as that the calculated envelope 100% securely ebraces the space of the movement.

By using the software as part of their services FES GmbH is able to offer serious added value to its customers and to gain an advantage in competition. Raphael Heilig managing director of Teraport GmbH comments on the new partnership: “We are pleased that FES GmbH can now, similar to how Teraport has been in the past, make a significant difference for their customers by taking advantage of this special technology.”