Strategic expansion of the Teraport solution at MAGNA STEYR Fahrzeugtechnik

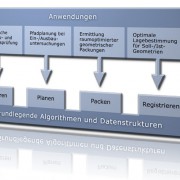

Following its expansion to cover a number of vehicle projects within the Company, the Teraport solution for the automated geometry checking process is now being strategically employed for quality assurance at MAGNA STEYR Fahrzeugtechnik AG & Co. KG. With this solution the individual components of the digital prototype are examined in respect of collision situations and clearance spaces. A decisive factor for the choice of Teraport’s software solution was its integration capability into heterogeneous system landscapes (PDM and CAD systems).

Flexible integration into the client’s system architecture

MAGNA STEYR is one of the leading developers and manufacturers of complete vehicles for diverse OEMs. As every automobile manufacturer prescribes development environments which are perfectly customized to its individual requirements, MAGNA STEYR must be in the position of being able to ensure a smooth and trouble-free work flow by maintaining diverse system landscapes. In order not to further increase complexity, the implementation of a standardized strategic geometry checking process was a fundamental criteria. This facilitates the interlinking of various system environments. To achieve this, however, a tool with open and flexible interfaces is required. The solutions from the highly efficient DMU-Toolkit not only meet these requirements, but also provide additional potential for an increase in the efficiency of the entire quality assurance process. Intelligent mechanisms such as, for example, inheritance logic or delta determination ensure that only those component combinations which have no history, or a modified history, require manual assessment.

Long-term collaboration

Wilhelm Dietrich, the Manager of integrated safeguarding in the geometric integration sector at MAGNA STEYR Fahrzeugtechnik AG & Co. KG summarizes his Company’s strategic decision to employ the Teraport solution as follows: “As both our clients’ varied requirements and project-specific general conditions result in an extremely complex and heterogeneous PDM landscape within our Company, it is particularly important for the optimal structuring of our specialized processes, that a process for checking geometric consistency which is as homogeneous, efficient, stable, and at the same time as methodologically flexible as possible, be made available in the form of a standardized tool. As regards the geometry checking tool, an ongoing customization of the interfaces, which must be as sustained as possible, and the continuous development of the application methods must be supported. In Teraport we have strategically chosen the right partner to achieve this.”