“Pushing the Limits” – Teraport Demonstrates Hands-On Innovation with veo

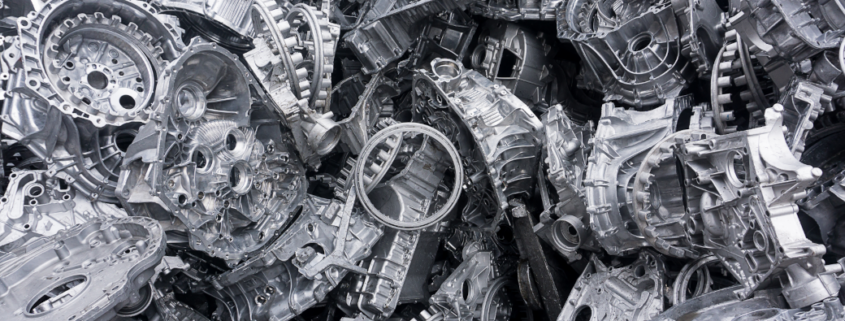

Innovative Approaches to Casting Development and Procurement

At the Aalen Foundry Colloquium 2025, Teraport GmbH delivered a widely acclaimed presentation on practical optimization opportunities across the entire cast part process chain—from development and procurement to sales. Under the title “There’s more to it!”, Dr. Stefan Wittmann, Product Manager for veo and Head of Algorithm Development at Teraport, demonstrated how early virtual analyses (termed veo quality gates) can significantly boost efficiency.

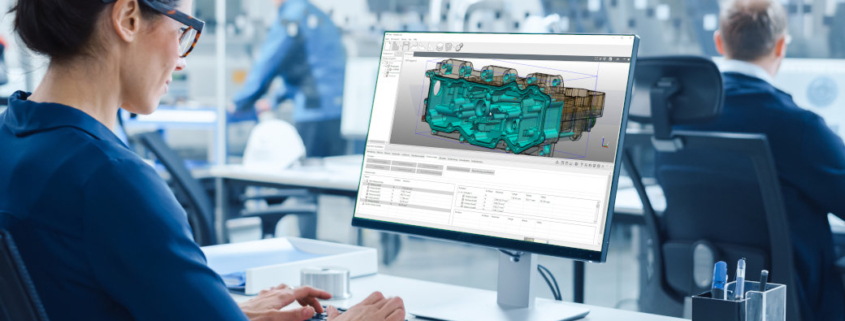

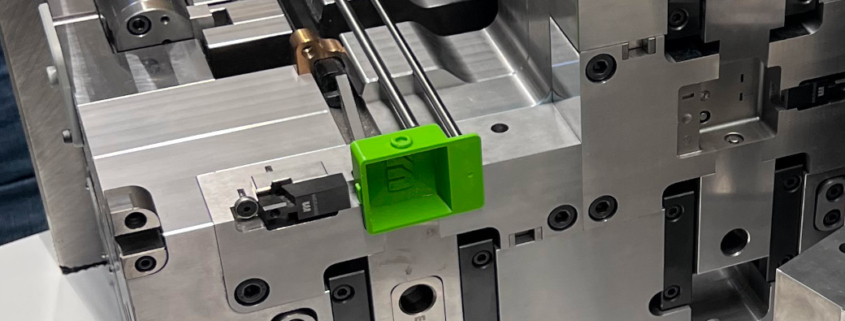

The presentation showcased a real-world project: the development of a housing for the pneumatic control of a dual-clutch transmission. Using this case, typical weaknesses—such as material accumulations and unfavorable wall thicknesses—were identified and optimized using Teraport’s in-house software solution, veo.

“Our quality gates enable us to detect problematic geometries early and resolve them efficiently—before costly correction loops become necessary,” Wittmann explained.

The economic aspect was also a key focus. In conjunction with mido, Teraport’s tool for automated tooling cost estimation, the company can provide reliable early-stage insights into costs, tool concepts, and production timelines.

“This creates transparency and a sound decision-making basis for both purchasing and sales—ensuring all project stakeholders are on equal footing,” Wittmann added.

Once again, Teraport underscored that modern casting development demands more than theoretical approaches—it requires tools that are practical, efficient, and economically viable.